Production process

Strictly Standardized

Every product from ValueSTek carries the wisdom of countless engineers and the hard work of production line workers. Born in a modern factory, each product undergoes an incredible journey from concept to creation, from parts to finished goods.

Let’s step into this modern factory and unveil the mysterious production process of ValueHub.

STAFF

QUALIFICATION

TRAINING

All personnel are required to receive skills training and obtain induction qualifications before taking up their posts.

ANTI-STATIC

TREATMENT

Anti-static treatment start from all aspects once entering the workshop, starting operation and environmental protecting etc..

1,000 CLASS (K-CLASS)

DUST-FREE

WORKSHOP

ValueSTek has a K-class dust-free workshop, which air cleanliness class meets the requirements of standard operating rooms.

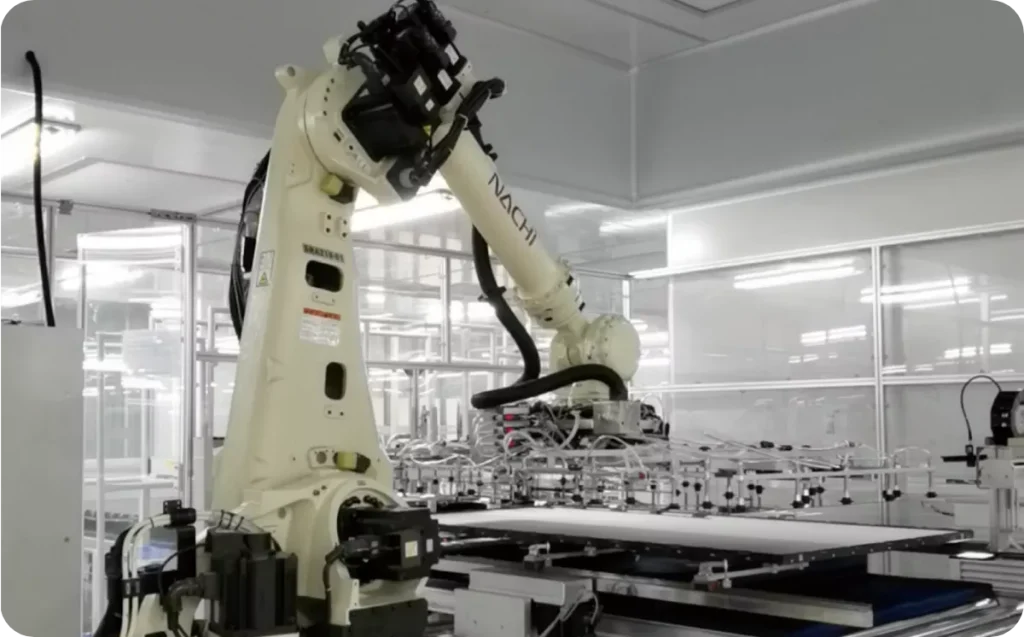

ROBOT OPERATION

Key positions are operated by robots to ensure operation precision.

AUTOMATIC

PRODUCTION

LINE

Full-automatic production line ensures high operation efficiency.

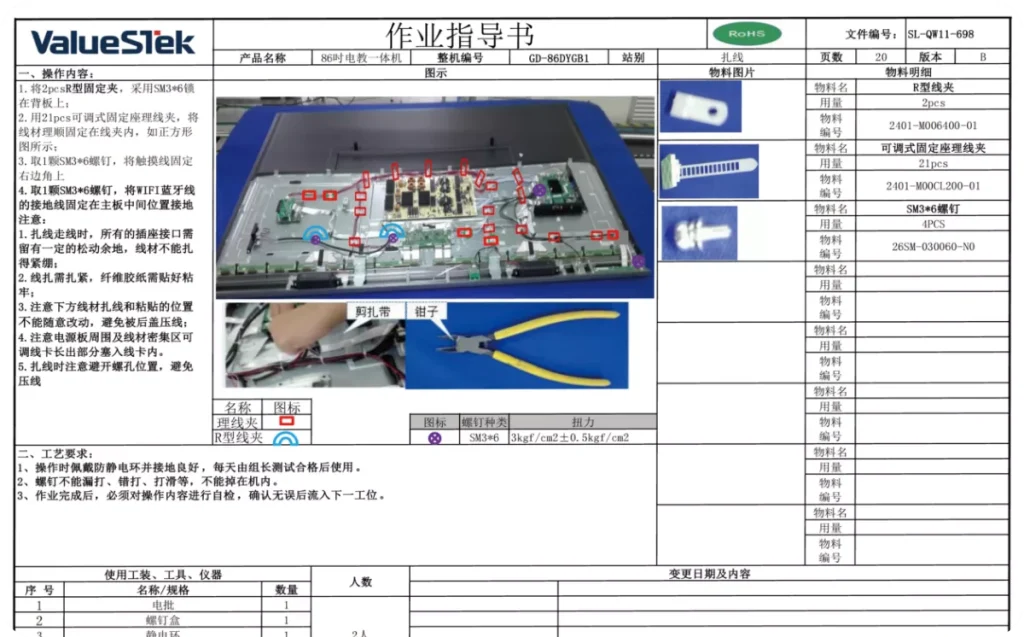

STANDARD

OPERATING

PROCEDURES (SOP)

SOP is available for each product and each position to ensure standard operation.

7S-ON-SITE

MANAGEMENT

Adopts 7S-on-site management to ensure high efficiency, high quality and high safety.

HIGH-TEMPERATURE

AGING

All products must undergo high-temperature aging test for the check of hidden troubles to products in advance.

KEY POSITIONS ARE

EQUIPPED WITH

PROFESSIONAL

TESTING TOOLS

Key testing positions are equipped with special testing tools, software and fixtures.

SAMPLING TEST

Each batch of products shall be subject to sampling test during production, 72-hour high temperature, low temperature, high humidity aging, transportation and drop test.

Transport

Simulation Testing

Samples from each batch undergo transport simulation testing to ensure the products are delivered safely to our customers.