9 Methods of Led Display Installation

LED display screens are divided into various installation methods according to different led display application fields. There are 9 common LED display installation methods. Today, this article will introduce led display screen installation in detail.

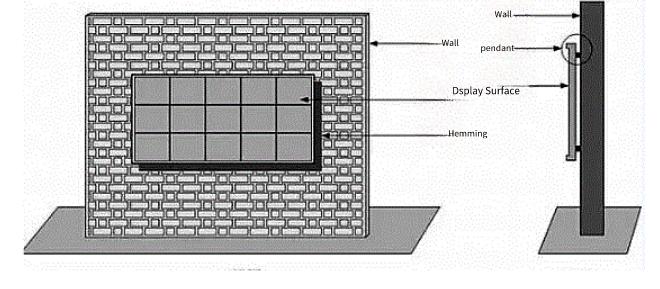

1. Led Display installation – Wall-mounted

This method of led display installation is usually used indoors or semi-outdoors. The display area of the led display screen is small, and generally, there is no space for maintenance access. The entire led display screen is removed for maintenance, or it is made into a foldable integrated frame. The led display screen area is larger, and the front maintenance design is generally adopted ( That is, the front maintenance design usually uses columns).

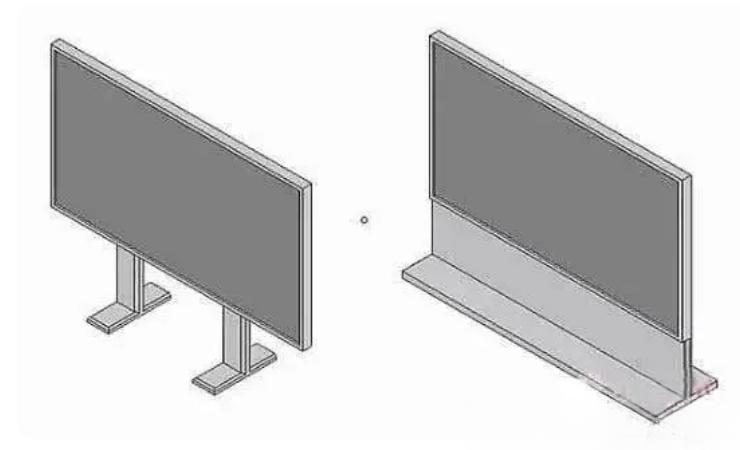

2. Led Display Installation – Column Installation

There are many column installation methods, generally used for outdoor advertising. A single column is suitable for a small led display screen. The double column is suitable for large led display screens. The closed maintenance channel is suitable for simple cabinets, and the open maintenance channel is suitable for standard cabinets.

3. Led Display Installation – Cantilever installation

It is mostly used indoors and semi-outdoors. It is generally used at the entrance of passages and corridors, and also at the entrance of stations, railway stations, and subway entrances. It is also used for traffic guidance on roads, railways, and expressways. The led display screen design generally adopts an integrated cabinet design or hoisting structure design.

4. Led Display Installation – Hanging Installation

It is similar to the cantilever installation, the led display screen adopts an integrated cabinet design, which is suitable for indoor and semi-outdoor screens.

5. Led Display Installation – Embedded Installation

The entire led display body is embedded in the wall, and the display plane is at the same level as the wall. It adopts a simple cabinet design and generally adopts front maintenance (front maintenance design), which can be used both indoors and outdoors, but it is generally applied to screens with small dot pitches and small display areas. Generally, it is mostly used at the entrance of the building, the lobby of the building, etc.

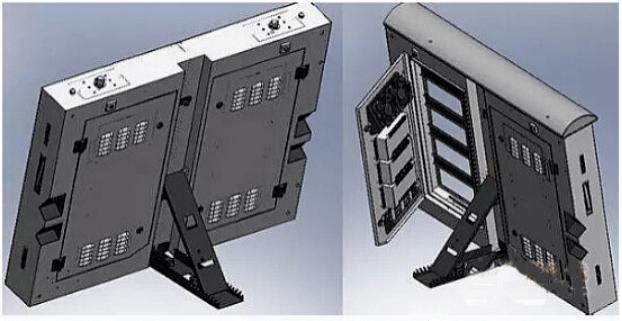

6. Led Display Installation – Standing Installation

It adopts an integrated cabinet design and also has a split combination design. It is suitable for indoor screens with small pixel pitch specifications and generally has a small display area. It is mainly used in LED TV design.

7. Led Display Installation – Roof Installation

The wind resistance of this led display screen installation is the key. Generally, it is installed with an inclined angle, or the module is designed with an inclined 8°, which is mostly used for outdoor advertising displays.

8. Led Display Installation – Football Field Fence Installation

It is used for displaying advertisements around the fence around the football field. The viewing angle of the led display screen can be adjusted with the inclination of the support frame. The mouth is designed with a soft silicone mask and a soft arc top design to avoid injuries caused by sports collisions.

9. Led Display Installation – Rental Hoisting

The size of the led display screen is determined according to the ordinary screen, and the hoisting screen should not be enlarged. The general requirement is below 6M*10M. Exceptions are special cabinet materials and curtain styles. The top is equipped with hanging beams and the bottom is equipped with bottom beams. Hanging beams are used to hoist the screen. The row and row boxes are connected by a hoisting mechanism, and the locks between the horizontal boxes are tightened. The hoisting mechanism is divided into gear type, cone-rod type, and bolt type. The gear type is more expensive and beautiful; the cone-rod type is moderately priced and reliable; the bolt type is the cheapest, most reliable, and cumbersome to assemble, and is suitable for situations where repeated disassembly and assembly are not required.